Battery Powered Underground Mining Vehicles

In 2015, we turned our product development attention towards designing a battery powered fleet that would respond to the mining industry’s growing need for cost containment through energy and mine design efficiencies, along with improving underground air quality for miners.

The MacLean EV Series product line gives our customers access to best-in-class technology, and then successfully integrates these components into mobile underground equipment by leveraging our multi-discipline engineering expertise, hard rock mining knowledge, and custom manufacturing experience. In other words, you can’t just understand the battery cycle, you need to understand the mining cycle in which it will be used.

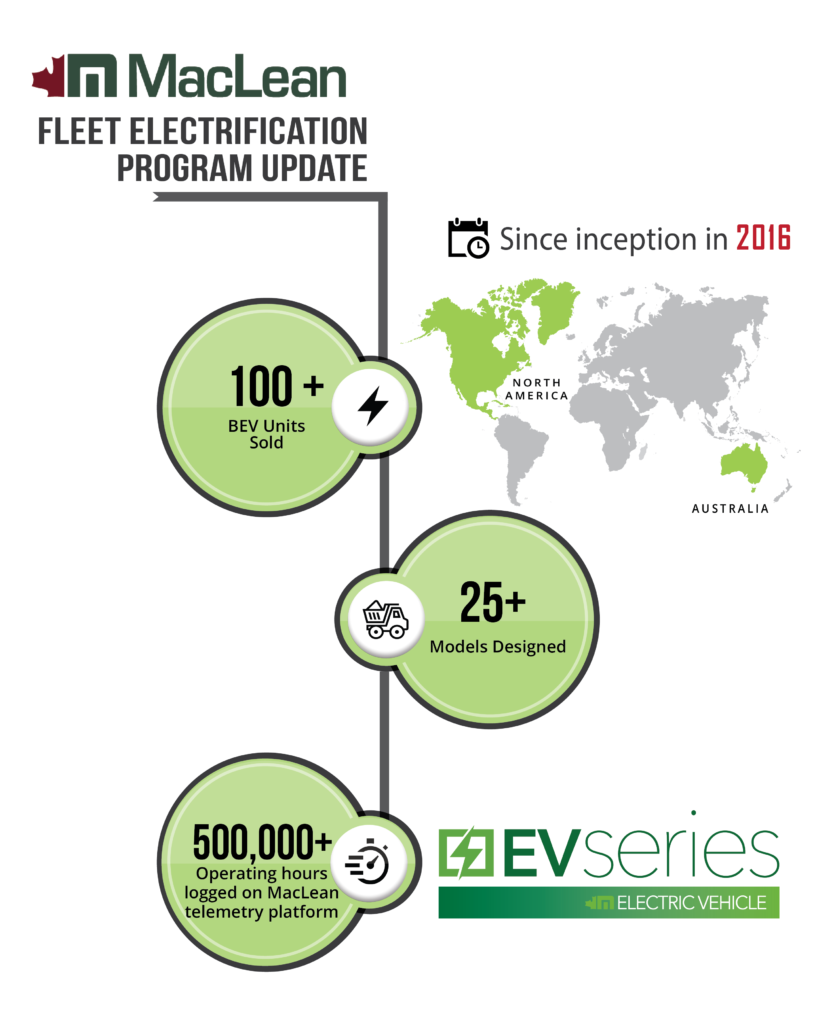

In 2016, we sold our first battery electric vehicle unit and by the end of 2019, we had sold 31 battery electric vehicle units, across five separate model lines. To date, MacLean has sold and commissioned battery electric production support mining vehicles at sixteen mine sites across two continents, amassing some 500,000+ operating hours.

MacLean is now taking its ‘EV-proven, EV-ready’ message to the mining world – for production support mining vehicles, considering the benefits of incremental battery electric vehicle introduction to allow for workforce training and supporting operator buy-in, which will pave the way for broader fleet electrification down the road.

- Depth of BEV experience and expertise within utility vehicle and ground support equipment categories – global technology leadership

- Ease of introduction from on-board charging design – no new electrical infrastructure required

- Ability to lease batteries to address site-level questions around end-of-life battery management – financial flexibility

When we set out to electrify the MacLean product lines in 2015, we identified a number of key requirements that would guide our design process.

- System must be adaptable to all MacLean mobile equipment (new and retrofit) and all mine requirements

- System must be compatible with existing power supply/voltage, and not require additional underground electrical infrastructure

- System must be flexible to enable incorporation of emerging technology

- System must deliver equivalent or better performance than diesel power configuration

- System must be scalable to as to provide the ability to deliver site and application-specific solutions

- System must deliver high degree of commonality across MacLean suite of underground mining vehicles

- Product development result = battery propulsion technology engineered for life underground, and customized to the application

- Elimination of all diesel particulate matter (DPM) and all other emissions associated with diesel engines

- Elimination of all air quality issues associated with dust generation and diesel exhaust porting

- Elimination of engine noise, vibration and heat associated with diesel engines

- Overall reduction of ventilation required to match diesel horse power ratings underground

- Overall reduction of energy required to condition ventilation air

- Overall reduction of parts per unit and resulting spare part stocking expense

- Elimination of diesel engine servicing and scheduled maintenance

- Elimination of diesel fuel costs – purchase, transportation to mine site, underground distribution, and surface storage

- Elimination of potential ignition source generally associated with diesel exhaust systems and wrapping or shielding

- Potential to reduce site-level GHG footprint

- Contingency against electricity grid transmission stability (i.e. brown-outs when peak load exceeded)

- Performance not impacted by altitude (battery propulsion does not require de-rating)

Related Products: