Remote Control Systems

The first package of commercialized products from our Advanced Vehicle Technology group, under the MacLean IQ Series product line banner, consists of three levels of remote-control technology.

From basic line-of-sight to surface operation packages, MacLean can deliver and support the appropriate remote-control solution for your unique underground mining environment. These remote-control systems are an excellent addition to the MacLean Ore Flow product line, to safely bring down draw point hang-ups and make block caving operations, in particular, safer and more productive.

Features:

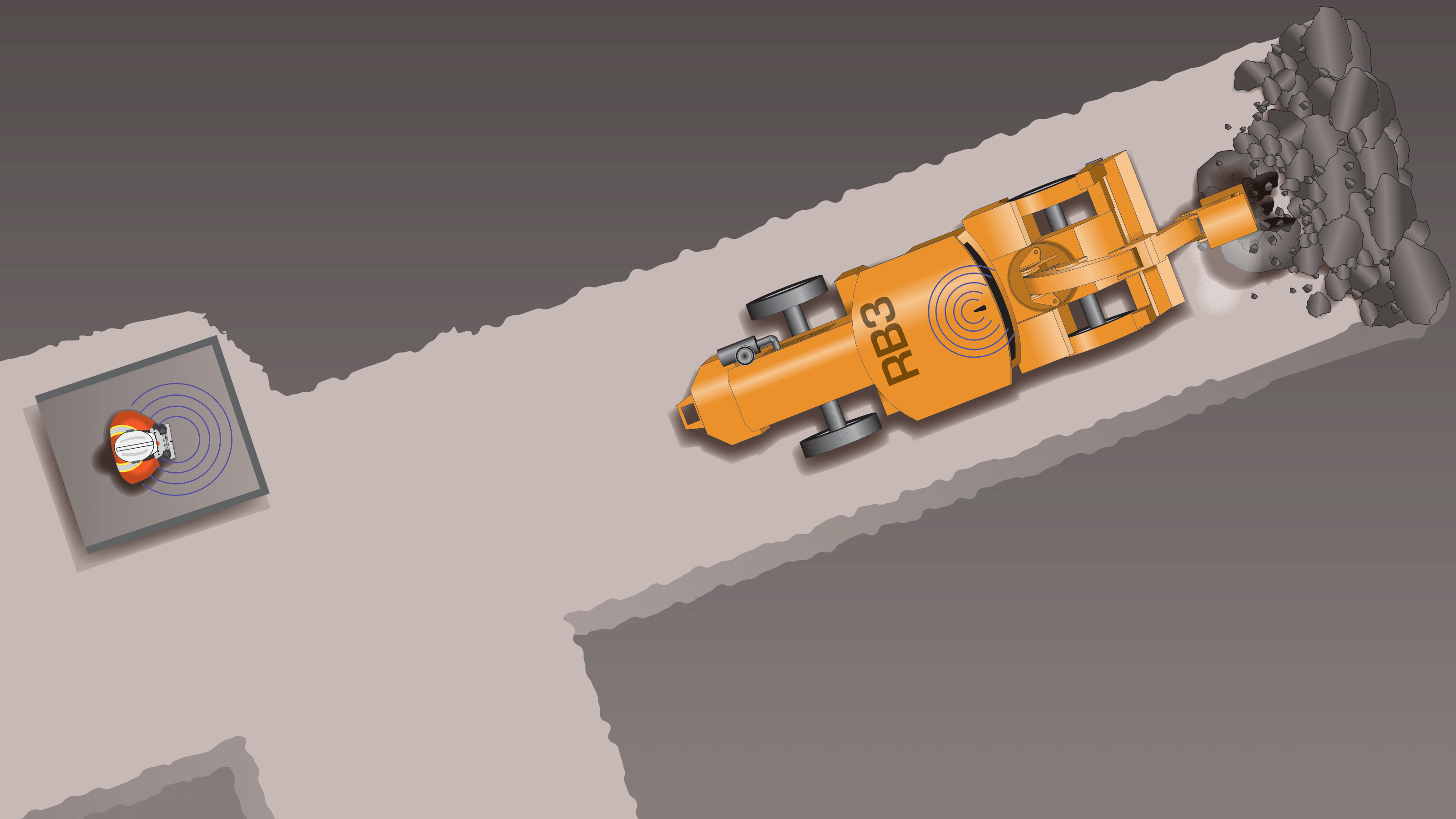

- Line of sight remote operations of MacLean mining vehicles, via radio signal in the underground environment

- Proportional controls allowing precise operation

- 900MHz radio communication

- 100m+ operation in visual line of sight, a uniquely paired transmitter and receiver ensures the machine responds to only one transmitter

- Status lights on the machine provide feedback to the operator

Benefits:

- Enhanced operator safety, especially in hazardous operating situations that would otherwise require working near large unstable fragmentation

- Improved operator ergonomics and reduced fatigue

- Increased productivity and reduced operating costs

Options:

- Wireless video system – 2.4 GHz line of sight transmission

Features:

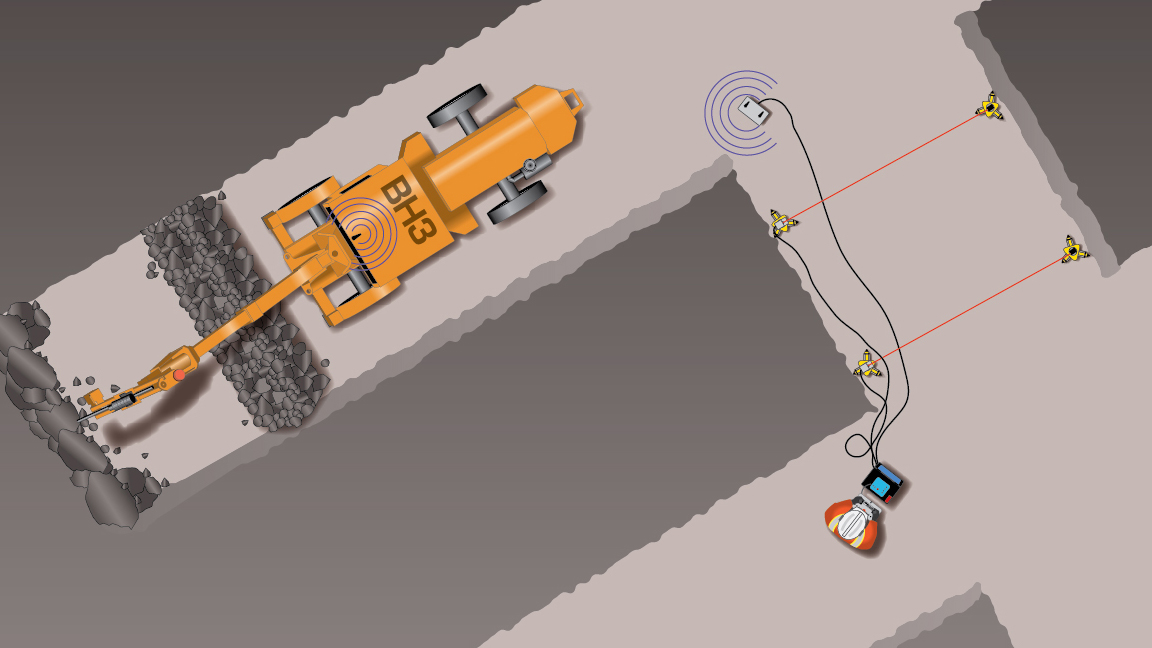

- Allows underground operation of the machine beyond visual line of sight

- All data traffic passed over a single 2.4GHz Wi-Fi link

- In standard configuration, the system is self-contained with no requirement for network infrastructure in the mine

- HD camera system configured for each machine

- Machine feedback package to monitor carrier and task signals from the control station

- Hardwired link from operator unit to communication hub and wireless link from communication hub to the machine

Benefits:

- Enhanced operator safety, especially in hazardous operating situations that demand ‘No Boots on Ground’

- Improved safety with further distancing from the exposure to heat, dust, noise, and other risks such as mud-rush

- Improved operator ergonomics and reduced fatigue

- Increased productivity and reduced operating costs

Options:

- Light barrier – controls access to the work area, safely stops the machine if personnel enter the work area

- Integration with mine network – if a network is in place at the mine, the tele-remote system can use this as a data link to operate over greater distances

- Battery-operated communication hub – removes the requirement for a hardwired link from operator unit to communication hub but requires a visual line of sight instead

- Options available for machine feedback packages tailored to machine types and customer workflows

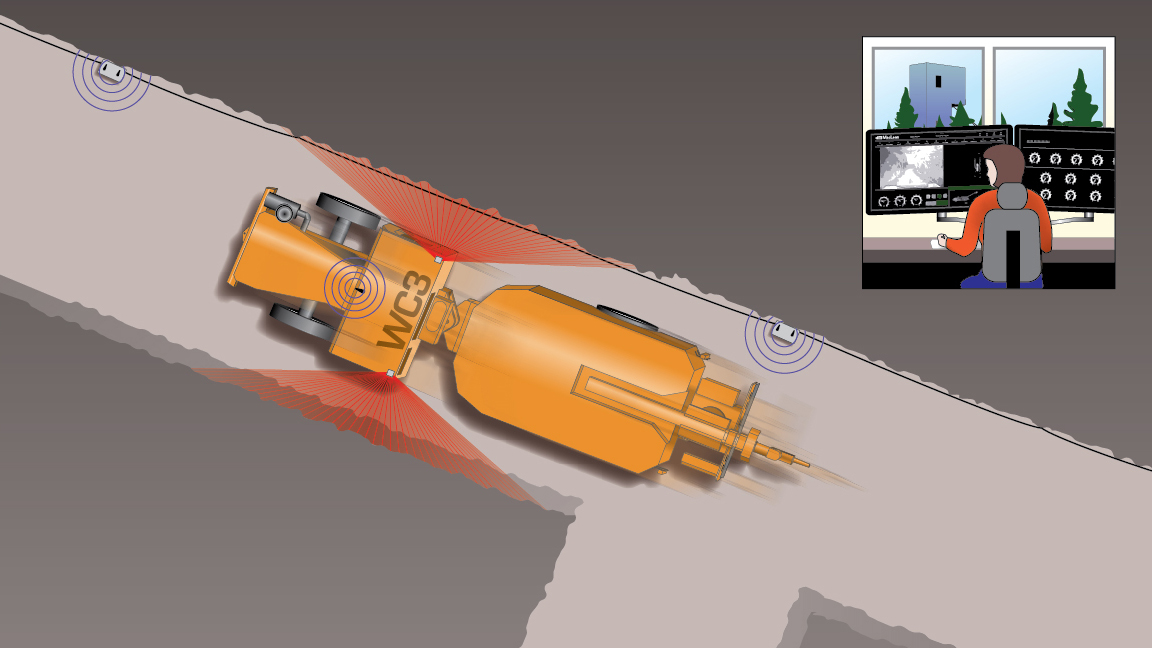

Features:

- Joystick Control Package with workstation and chair

- Two (2) or more widescreen displays (specification dependent on application)

- Comprehensive machine feedback package to give an in-cab experience

- Localization and Autonomous packages available as options

Benefits:

- Office like work environment to completely remove operators from underground mining environment in critical ground conditions

- Increased productivity as operator availability increases due to reduced commute times

- Increased machine utilization leading to a reduction in total capital equipment requirement

- Improved productivity and operator ergonomics

- Allows for further automation and use of multiple units from single operator stations

Options:

- Machine localization within mine map

- Integration with mine safety system/automation safety system

- Integration with automation traffic management/ dispatch system

- Integration with existing mine network

- Driver assistance features – obstacle detection, collision avoidance, speed limiting