MACLEAN MEDIUM REACH SECONDARY BREAKERS SB12 (993MR)

The MacLean success story at Palabora Copper Mine in South Africa focuses on three MacLean Hang-up Rigs that have been working underground for 15+ years. The mine endorses MacLean’s commitment to creating value for mine operators, accomplished with the highest safety, productivity, and reliability.

The SB8 and SB12 Secondary Breakers (993MR, previously) are a part of MacLean’s Ore Flow suite, the leading ore recovery fleet in global underground hardrock mining.

The Rig: MacLean Medium Reach – Secondary Breaker

The Project: Palabora Copper Mine, South Africa

PMC has been operational since 1956 and is the country’s major producer of refined copper, producing approximately 60,000 tonnages of copper per annum processed from 30,000 tonnes of ore production per day.

THE ISSUE:

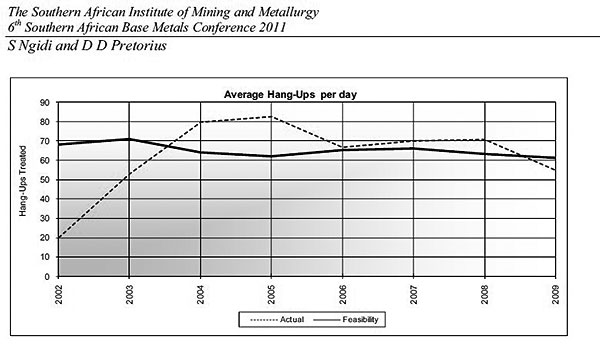

Mass mining of low grade ore in deep underground mines using Block or Panel Caving methods gets affected by interferences associated with the caving processes; especially those related to gravity flow, such as, hang-ups and oversize rocks.

Medium and high hang-ups or oversized fragmentations beyond the capacity of LHDs (scoops) deployed for extraction need to be cleared quickly and safely, as they not only stall production, but also create stresses on mine structures, such as draw point brows and extraction-level tunnels. Damages can go as far as causing footwall heave and failure of tunnel sidewalls. All this adds to production losses and increased mining cost.

THE SOLUTION:

MacLean’s Medium Reach Secondary Breaking rigs, designed and built as a part of MacLean’s Ore Flow Suite, were pressed into operations and since then have become an integral part of daily operating regime for bringing down hang-ups and releasing blocked drawpoints. For past 15 years these rigs have brought down thousands of hang-ups thus ensuring smooth running of the mine and the mill, and a safe and sustained block cave operation.

The MacLean Medium Reaches are driven to the blocked drawpoint using line of sight radio remote controls (tele-remote is also an option), thus operating from a safe distance to target a previously stabilized key-stone in the hang-up; first by drilling up to 12 meters height in the draw bell and then loading that with an explosive or emulsion charge.

The resulting secondary fragmentation brings down the hang-up now as freely flowing ore that can be easily mucked out. A water cannon (MacLean’s model – WC3) can be used to stabilize the hang-up prior to such operations and Medium Reaches can then be called in if the hang-up does not come down with washing attempts.

THE RESULT

- Increase in Ore recovery rate

- Substantial increase in operating efficiency & safety

- A turning point in the mines’ chase for ore recovery

Testimonial:

“Three MacLean Medium Reach Rigs in our mining equipment fleet are the warriors against hang-up challenges that we face every day. These Secondary Breaking units were designed to eliminate ore flow blockages and release trapped reserves above the draw point brow safely and effectively and thus have helped us greatly in keeping the mine running for the past 15 years. MacLean’s John-Paul Theunissen and his team of service techs and customer support parts representatives have done excellent work in supporting these rigs over the years, based in large part on their branch location at the mine site, right here in Palabora.”— Rendani Nemathithi, Superintendent Cave Operations, Underground Mining Operations

For additional information:

Viv Bhatt

Product Manager – Ore Flow, Drill & Blast

MacLean Engineering, Canada

vbhatt@macleanengineering.com

+1-705-888-5796